HafcoVac Anti-Static Vacuums

HafcoVac Anti-Static vacuum cleaners are designed and constructed to operate safely in hazardous locations. They are well suited for the safe cleanup of hazardous dusts, wet and dry materials, sludges and slurries within environments that are susceptible to explosions or flammability as part of a housekeeping control program. The use of HafcoVac Anti-Static vacuums are a safe, reliable and cost-effective choice for facilities working with substances and materials that can produce combustible dusts and buildup of static electricity.

HafcoVac Anti-Static Industrial Vacuum Cleaners are manufactured in the USA at our NJ facility to perform tough applications within industries that have a need for safety, reliability and high performance. Our goal of helping facilities safely and effectively remove dust and debris in their facility is our sole focus. We understand that safely removing this debris is a significant challenge in the workspace and that safety is paramount and efficiency is always desired. HafcoVac Anti-Static Vacuums play a powerful part in the process of keeping productivity high and housekeeping safe and simple.

HafcoVac Anti-Static Vacuum Cleaners components are bonded together ensuring that no part is isolated from its path to ground. The absence of moving internal parts also greatly minimizes maintenance. Consumable items such as filters and filter bags need replacement depending on the usage. Maintenance of a HafcoVac Anti-Static Industrial Vacuum is pretty much relegated to consumable items such as filters and filter bags.

All of our vacuums come with a Lifetime Warranty for peace-of-mind and all are made in the USA.

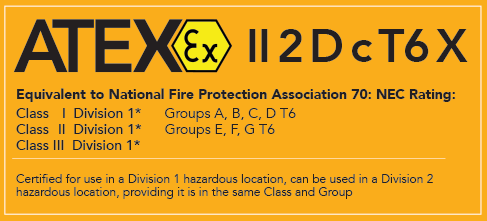

HafcoVac Anti-Static Grounded Units ("x" model designation) machines meet the criteria for intrinsically safe operation. No moving parts, non-electric and fully grounded which means the unit will not spark or generate dangerous amounts of heat. HafcoVac vacuums are ATEX certified for use in National Fire Protection Association (NFPA) 70: NEC rating Class I, Division 1 (Zone 1 only), Groups A,B,C,D T6 and Class II, Division 1, Groups E, F, G T6.

Intrinsically Safe, Our Compressed Air Vacuums

Contain No Moving Parts

Eliminates the possibility of ignition from mechanical friction or contact.

Use No Electricity

Eliminates sparks from motor arcing, shorts, switches, etc.

Are Fully Grounded

Each explosion-proof vacuum configuration is fully grounded. This ensures that dangerous static electricity will not accumulate.

Hafcovac Vacuums

Tackle Any Cleaning Challenge

See our Full Line of OSHA Compliant, Explosion-Proof, Dust Ignition-Proof and Hazardous Location Vacuums

Real world tested in these industries:

Same Day Shipping

Quick shipping! Most models in stock for immediate shipment. Configure and ship within 1 business day.

Lifetime Warranty

With no moving parts to wear out, you will never burn out an electric motor, no matter how harsh your application or environment.

Live Support

Personalized support guaranteed! No automated responses. When you contact us, we answer!

Certifications

NRTL Listed

ATEX Certified Explosion Proof

OSHA Compliant Certified

NFPA Certified

Comdust Certified

Wet & Dry Use

Anti Static Explosion Proof

Made In The USA

HafcoVac ATEX Certified

HafcoVac vacuums are ATEX certified for use in National Fire Protection Association (NFPA) 70: NEC rating Class I, Division 1 (Zone 1 only), Groups A,B,C,D T6 and Class II, Division 1, Groups E, F, G T6.

HafcoVac Anti-Static Grounded Units ("x" model designation) machines meet the criteria for intrinsically safe operation. No moving parts, non-electric and fully grounded means the unit will not spark or generate dangerous amounts of heat.

These machines are designed specifically for use in hazardous locations, building in a double safeguard of conductive static dissipative materials and connections coupled with complete grounding of all components of the unit.

The

Hafcovac Advantage

Intrinsically Safe

Our explosion-proof pneumatic vacuums:

Contain No Moving Parts

By containing no moving parts, our vacuums eliminate the possibility of ignition from mechanical friction or contact.

Are Fully Grounded

Explosion-proof vacuum configurations are fully grounded, ensuring dangerous static electricity will not accumulate.

Use No Electricity

Eliminates sparks from motor arcing, shorts, switches, etc.